Question:

In what situation and applications should I use a Hazardous Area cable joint over a standard resin-filled joint?

Answer:

A Hazardous Area joint kit should be used if you have a requirement for your cable jointing solution, to be flame retardant, halogen-free or hydrocarbon resistant.

All of our 3M Hazardous Area joints have been tested extensively to prove their performance within hazardous and harsh environments and the effects of hydrocarbons and chemical solvents on resins and joint bodies.

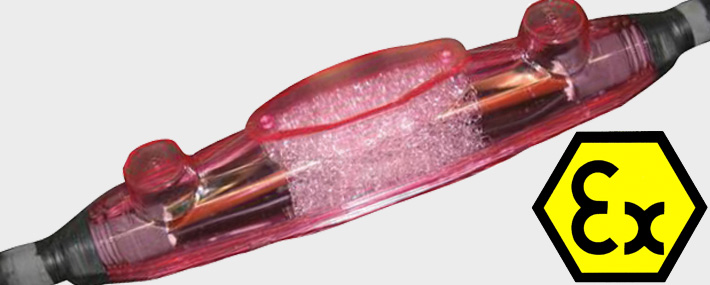

The LVI-3 range of cable joints have been successfully installed within ATEX rated Hazardous Area including mines and quarries, underground applications, petrochemical sites and offshore areas where there is a risk of flame or explosion.

The specialist joint shell, which is flame retardant, hydrocarbon resistant and halogen free, is filled with a specially designed polyurethane resin, which is a highly modified joint resin mix, which makes the resin flame retardant, halogen free and virtually unaffected by immersion in either hydrocarbon or chemical solvent solutions.

If you found this article helpful or interesting, please share it!