Question:

I’m about to use a bonded screen removal tool for the first time, how do I make sure it works correctly and the screen is properly removed from the cable?

Answer:

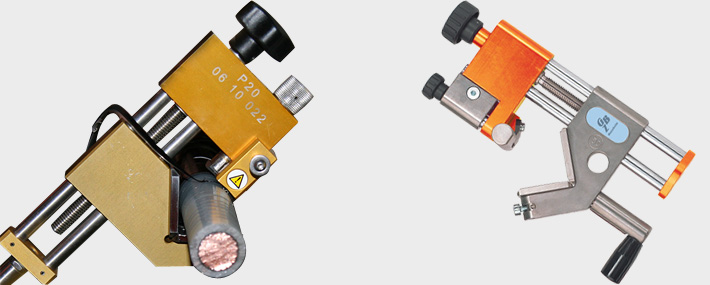

When terminating or jointing MV cables with a bonded semi-conductive screen, this will have to be shaved from the cable primary insulation to the dimensions given within the accessory installation instructions. There are a variety of tools available that will perform this task, however when using a purpose-made screen removal tool the following points should be noted to ensure the cable is prepared correctly:

Ensure the blade is set to the correct depth. Excessive removal of the cable insulation could increase the electrical stress at the point of removal, particularly with air-clearance terminations (Heatshrink and ColdShrink types). The best way to ensure the correct depth is to practice on a piece of unused cable first.

Some tools require the application of silicone grease to the semi-conductive screen in order to lubricate and ease tool rotation. Fully familiarise yourself with the usage instructions supplied with the tool you are using and practice on a few lengths of unused cable to “get the feel” of the tool.

Ensure the core is perfectly straight. Any bend in the cable can lead to the screen not being removed evenly around the circumference. This could happen to the underside of the cable and may not be immediately noticed, potentially causing partial-discharge issues.

Using a specialist tool usually results in a perfectly prepared core, but if small amounts of bonded semi-conductive screen are left on the cable these can be removed with the use of a fine abrasive, non-linting cloth (120grit minimum). Care should be taken to only abraid cables circumferentially (NOT longitudinally) to avoid creating a partial-discharge path along the cable insulation.

Once you have prepared your core(s), the primary insulation will require cleaning to ensure any loose particles are removed. Always clean polymeric insulation from the exposed conductor end, along and TOWARDS the semi-conductive layer in one direction, avoiding inadvertently contaminating the insulation with any semi-conductive compound residue.

There are a number of different types of bonded screen used on cables. Although the aforementioned procedures are common to most polymeric semi-conductive compounds, it is important to confirm that your tool and cable/s are compatible before commencing work.

ETS Cable Components offer a variety of quality-manufactured cable preparation tools from GBZ-Mannheim and Nexans. Please contact our Sales Team for further information, prices and advice.

If you found this article helpful or interesting, please share it!