The safe and correct working of accessories used for cable terminations is dependent upon many issues from the correct specification of the product through to competent installation. The following is a list of (maybe obvious) do’s and don’ts which should be adhered to.

The “Do’s” of Cable Terminations

– Do ensure the correct products are specified – such as ColdShrink, Heatshrink or Screened Connectors.

– Do check associated products are compatible and safe to be used together.

– Do check the accessories and cable dimensions match.

– Do ask the manufacturer or distributor for more information on the product is required.

– Do prepare the cable and accessories in a suitable environment (clean and dry).

– Do ensure all staff are trained and competent to carry out the termination.

– Do use the correct tools for the job.

– Do ensure these tools are properly maintained and functioning properly.

– Do make sure the cable lugs/terminals are installed correctly – for crimp connectors, ensure the correct die sets and compatible tooling.

– Do smooth any sharp edges on lugs caused by crimping dies.

– Do read and follow installation instructions carefully.

– Do not forget to install the earthing system correctly.

– Do ensure heat shrink and cold shrink components are correctly positioned before shrinking or removal of cores.

– Do fully test the terminations after installation.

The “Don’ts” of Cable Terminations

– Don’t rush any part of the job.

– Don’t cut corners or take short cuts.

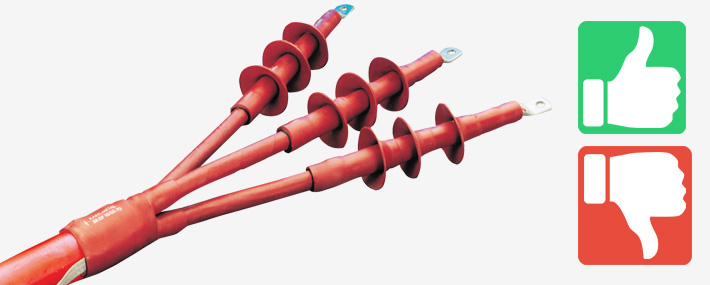

– Don’t allow sheds on adjacent cores of a three-core termination to touch – This can lead to discharging.

– Don’t allow any secondary wiring to be damaged when installing heat shrink sleeving.

If you found this article helpful or interesting, please share it!